Haydenshapes FutureFlex Upcycled Cloth – you might have seen this floating around last week, a few sites wrote about it, was on the gram, even showed up in my YT feed. So while we generally might not post something that’s showed up everywhere (especially as we’re posting the PR stuff), this is really interesting and needs to be shared/read, etc by all.

Below is a run down on what Haydenshapes FutureFelx Upcycled Cloth is all about, how he came about creating it, some videos, images, etc. Please take five minutes to read through it all if you haven’t already somewhere else.

In the manufacturing of a single surfboard, around 30% of foam and fiberglass waste is created which typically ends up in landfill. A few months ago Haydenshapes launched a pop up floating workshop titled ‘Remote’ where Hayden put to test a number of design ideas utilising how surfboard manufacturing waste could be put back into the creation of a board. It was here the concept of ‘FutureFlex ‘Upcycled’ Multiaxial Cloth was born.

WHAT IS FUTUREFLEX UPCYCLED CLOTH

What is FutureFlex Upcycled Cloth?

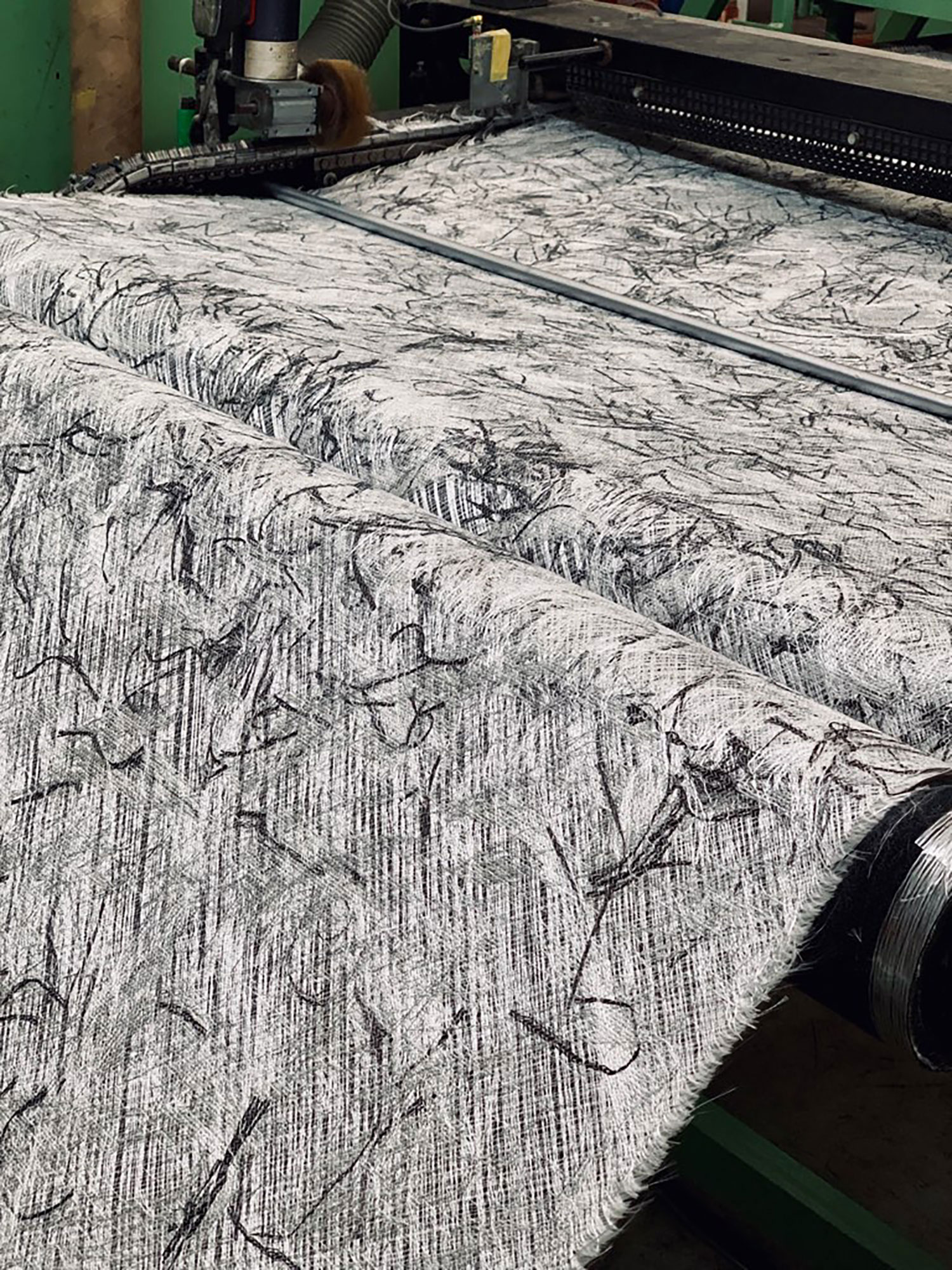

An upcycled fiberglass cloth that is made with chopped carbon fiber and fiberglass off cuts, aerated, then woven into new multi-axial cloth. It is a sustainable material created with the ethos of reducing and repurposing waste created from surfboard manufacturing back into creating a new product. Visually, the monochromatic black and white synonymous with FutureFlex is honoured by the disbursement of the chopped carbon.

How does it compare with a traditional fiberglass cloth?

The FutureFlex Upcycled Cloth Multiaxial fabric is a 6oz cloth made up of a stitched biax with the chopped strand upcycled fiber content in between the layers. You can use it in a single layered wet layup bio-epoxy amination each side of the board to create a standard weight lamination with a nice homogeneous flex pattern. Compared with a traditional surfboard lamination of a single 4oz bottom with a 2x4oz deck, you will use about 10% more resin, yet the durability and strength of the lamination is substantially higher through the multiaxial and random nature of the FutureFlex Upcycled fabric.

HOW DID THE IDEA COME ABOUT?

How did the idea come about?

In 2018, Hayden was invited to the IWC Schaffhausen manufacturing facility in Switzerland, watch makers of over 150 years, and saw first hand ways that metal off-cuts were collected and repurposed back into product. From here, Hayden linked up with Damien at Colan Australia to weave the upcycled cloth and the first sample board was built on board Haydenshapes ‘Remote’ pop up floating workshop in October 2019.

Are cloth samples available now?

All manufacturer enquiries regarding the up-cycled cloth can be made directly via [email protected] ATTN: Hayden.

When and where will it be available?

Right now we have progressed past the first rounds of samples and are now focusing on scaling up and making the upcycled cloth available. The two key focus areas will be development of machinery to cut and sort the waste fiber and a hopper/spreader to work with Colan Australia’s existing multiaxial weavers. This will take capabilities from small quantities to hundreds of meters. Ways to collect / receive carbon and fiberglass waste from not only Haydenshapes, but other manufacturers, is also being explored. A decade ago Hayden worked directly with Damien and the team at Colan Australia on developing carbon fiber tapes which are now used by the majority of surfboard manufactures industry wide.

The goal for the ‘FutureFlex Upcycled Multiaxial cloth’ is to again provide a material to the wider industry however in this instance, create something that is sustainable and works to minimise the environmental footprint by reducing the waste. Like the carbon tapes available, this cloth will also be distributed by Colan Australia however will sit within the ‘FutureFlex’ brand offering.

THE INTERVIEW

What up-cycled design concepts did you work on on board ‘Remote’?

I wanted to test 3:

- A stringer created using bio-resin, EPS foam and fiberglass / carbon fiber waste.

- A tail pad created with foam waste and bio urethane.

- Laminating an up-cycled cloth made with hand chopped carbon fiber and fiberglass waste off-cuts that I prototyped with Colan Australia. This was the key one I wanted to focus on in the film.

What is your feedback on each one:

The up-cycled stringer I made is currently a little too flexible and we need to reduce the weight, however I think I could continue to work on this concept and improve it. This does replace the wood, yes, and it is also regenerable from manufacturing waste.

The tail pad is a bit heavy to be honest and only really suited to a cruisy style of board like a twin fin or single fin. The theory works, but it needs refining to get more foam content into the pad.

The up-cycled cloth is an idea that definitely has legs. This was the first sample that I surfed and it actually felt really good. The carbon is currently a bit clumpy which can be refined but overall it felt very natural to your surfing and the flex was in time with you when making turns. It has a more homogenous flex compared with the lively flex of the carbon rail FutureFlex, but it still feel exciting under your feet, especially in a twin fin shape.

What are your plans with this cloth?

Right now I am working with Colan Australia on how this cloth can be scaled up from it’s current form which is having the off-cuts chopped by hand, aerated then fed into the weaver by hand. Designing and developing the process and machines to scale the process up to be able to make hundreds of meters in a run is the next challenge.

Over a decade ago, I worked with Damien and the Colan team on engineering unique carbon tapes for FutureFlex. The tapes we designed are currently the ones used now by the majority of surfboard brands industry wide. I’d love to work on materials like this the up-cycled cloth and others that everyone can access.

Read the rest of this interesting interview over at Haydenshapes. There’s a bunch more questions that Hayden has answered that will give insight into what he’s doing, his thought around it all – good read.